Company

Brief Introduction of Aluminum Profile

Posted: 2015-10-08 22:14:11 Hits: 1742

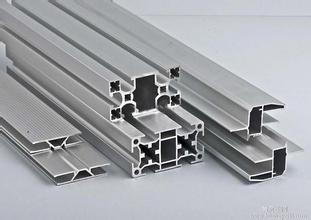

Aluminum profile is the profile which processed by hot melt and extrusion and has different shapes. It has three manufacturing steps: casting, extruding and coloring, the coloring including: oxidizing, electrophoresis coating luoro-carbon coating and powder coating, etc.

Aluminum profiles can be divided into two types, according to its application:

1. Industrial aluminum profile: mainly used in aircraft, trains, industrial radiators, automobile, electrical appliances.

2. Aluminum alloy profile: mainly used in building windows and doors, curtain wall, interior decoration and building structure with aluminum.

In accordance with its surface treatment, aluminum profiles can also be classified into four categories:

1. Anodized aluminum profile: its surface has been anodized, and colored by electrolytic or organic.

2. Electrophoretic coating aluminum profile: its surface has been anodized and electrophoretic coated.

3. Powder coating aluminum profile: its surface has been organic polymer powder coated.

4. PVDF coating aluminum profile: its surface applied polyvinylidene fluoride paint for coating.

Key Indicators:

1. Quality of appearance: it is not allow electrical burns and shedding of oxide film on the surface of anodized aluminum profile, otherwise it will influence its application. The coating should be uniform, clean and smooth, defects such as wrinkles, cracks , bubbles, flow marks and shedding of paint are not allow. The appearance of aluminum alloy profile has impact on exterior decorative effect of buildings, so its surface must be covered that to prevent scratches, bumps and corrosion during transporting and stocking.

2. Thickness: the thickness of profile is one of the main factors that affect the strength of workpiece, the main profile is the force in the project area. For instance, windows require the thickness of profile must be more than 1.4mm.

3. Chemical composition: aluminum profiles with different brands and delivery status have different chemical composition and mechanical properties, its needs customers to check carefully with standard or contract.

4. Color and color difference: the aluminum profiles also have different color and color difference. Customers need to consider its impact on the building structure.

5. Corrosion resistance: the corrosion resistance is a key indicator, it can reflect the performance of aluminum profiles, and also has impact on its application.